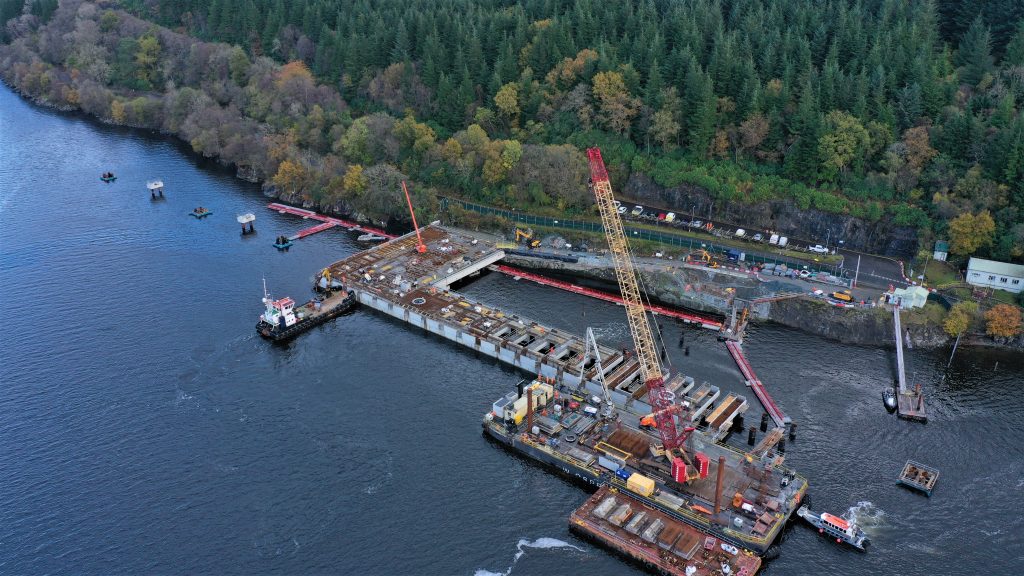

Since my last update, the construction of the jetty has really progressed and it’s rewarding to see refurbishment works taking shape. Bringing the Royal Navy’s surface fleet into Glen Mallan requires a new jetty structure, five new mooring dolphins, two pedestal cranes and lots more infrastructure.

What we’ve done so far

We’re also installing four new navigational markers, which are special lights that will enable pilots to safely navigate in and out of Glen Mallan. The lights are mounted on large steel tower structures rising up to 30 metres from the seabed. The tops of these towers will be installed by a crane barge later in the year. The lights are powered by solar panels without using the national grid, which has saved the team at DIO and VolkerStevin the job of having to lay electrical cables into the seabed. To minimise disruption to local vessels and the public, the lights will only be visible along certain routes.

We’ve also installed 20 fender panels along the front of the new jetty structure. Once all the fender panels are in place this will create what is known as a continuous berthing face, enabling all vessel types to use the new jetty. Two modular fender spacer units have been fabricated for the Queen Elizabeth Class aircraft carriers that move with the tide to prevent the vessel’s overhanging flight deck from colliding with the jetty. They are currently being constructed in Holland.

What’s next

We’ll also be installing two modern pedestal cranes which will help to ammunition all vessels safely and efficiently, and will be replacing the old rail mounted portal cranes which have reached the end of their lifespan.

Challenges we navigated through

The past year has been challenging, but extremely rewarding and I’m proud of the progress that we’ve made so far on the refurbishment works. Without the hard-work, commitment and collaboration of our staff, contractors and local companies, we wouldn’t have made the progress we have today.

We take the safety of our workers very seriously, who continue to work to deliver this critical infrastructure programme for Defence. We’re regularly keeping in touch with them and following the latest government guidelines to help protect our workers against Coronavirus.

In Spring 2021, the refurbishment of the jetty will be complete, helping to provide the Armed Forces with the capabilities they need to maintain Britain’s security in an ever-changing world. Keep an eye out on our Inside DIO blog for further updates on Glen Mallan.